EVA Cutting and Layup Machine

Used for automatically cut and layup first EVA film in solar panel production line

EVA Cutting and Layup Machine

Used for automatically cut and layup first EVA film in solar panel production line

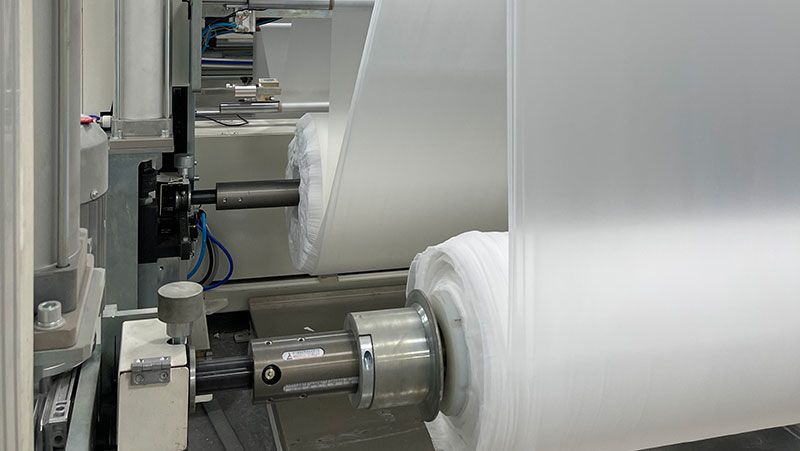

An EVA cutting & layup machine is used for EVA film loading, cutting, layup and hole punching.

Technical Parameters

| Item | Parameters |

| Panel size | (1,680-2,650)*(992-1,500)mm |

| Cycle time | 20s |

| Cutting accuracy | ±1.5mm |

| Layup accuracy | ±1.5mm |

| Overall dimensions (L*W*H) | 6,000*2,320*2,000mm |

| Voltage | AC 380V, 3 phase |

| Power | 5kW |

| Air pressure | 0.5-0.7MPa |

| Maximum material roll diameter | ≤800mm |

Features

- The layup machine can directly mix tailings with new materials through standard hot melting procedures;

- Automatic correction, automatic detection of joints and automatic material throwing for higher production efficiency and stability;

- The hob cutting method prevents the material from be sticked onto the cutter to improve the cutter durability and efficiency.

Horad, as a specialist manufacturer of intelligent PV panel production line, is committed to providing complete PV module manufacturing solutions for global customers within the photovoltaic industry like solar panel manufacturers. Our portfolio includes not only automatic solar panel production lines, but also individual equipment for PV modules production, from glass loading equipment at the beginning to solar panel assembly and testing equipment at the end. If you are looking for complete solar turnkey lines for photovoltaic module manufacturing, Horad will be your reliable PV solar panel line supplier.

Related Products

Get in Touch